Asosiy ma'lumotlar

Asosiy turi:

1.Izolyatsiya qilingan yagona o'tkazgich uslubi

2.Egizak dirijyor uslubi

3.Izolyatsiya qilinmagan shnur uchi yenglari

Xususiyatlari

Umumiy tasavvurlar: 0,25 ~ 150 mm²

Rangli kodlash va kolba o'lchami DIN 46228, 4-qism (0,5 ~ 50 mm²)

Galidsiz, olovga chidamli qabul qilishi mumkin

105 ℃ (PP) 120 ℃ (PA) ga qadar issiqlikka chidamli

Material:

99% toza mis

Sintetik: polipropilen (PP), poliamid (PA)

Yuzaki

Korroziyadan himoya qilish uchun qalay bilan qoplangan

Buyurtma ma'lumotlari

Endi kichikroq talablar uchun qulay plastik qutilarda ham mavjud.Oddiy sharoitlarda bizda sumkani qadoqlash uchun MOQ talabi yo'q.

Texnik ma'lumotlar

Supero'tkazuvchilar material (Tez ulanish oralig'idan tashqari)

| Mis | 99,9% toza |

| Mustahkamlik chegarasi | 200MPa |

| Egiluvchanlik reytingi | 35% |

| Yakuniy metall holati | Mahsulotning bir qismi tavlangan |

| Kislorod tarkibi | 50ppm maksimal |

|

|

|

| Guruch | 30% sink 70% mis |

| Mustahkamlik chegarasi | 580 Mpa |

| Egiluvchanlik reytingi | 6% min |

| Yakuniy metall holati | Mahsulotning bir qismi tavlangan |

|

|

|

| Material | Qalay |

| Qalay tarkibi | 99,90% |

| Boshqa metallar | Qo'rg'oshin + Surma |

| Qoplama qalinligi | 1,5 mikron |

|

|

|

| Umumiy o'tkazuvchanlik | 98,5% IACS |

| Umumiy qarshilik | 1,738 mikro-ohm sm |

|

|

|

| Material | Neylon 6 yoki neylon 66 dan tashqari hamma uchun PVX - IQC uchun |

| Buzilish kuchlanishi | 1,5 k V(min) |

| Izolyatsiyaga qarshilik | 100 meg ohm dan yuqori |

| Ish kuchlanishi | 300 V gacha AC/DC |

|

|

|

| Oldindan izolyatsiya qiling | -40 ℃ dan +150 ℃ gacha |

| Guruch | 145 ℃ |

| Qalay qoplangan | 160 ℃ |

XUSUSIYATLAR

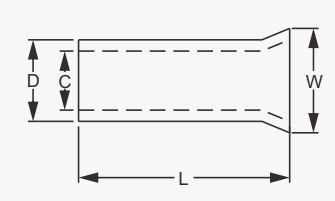

| Ko'ndalang kesim (mm²) | Element raqami | Olchamlari (mm) | AWG |

| Ko'ndalang kesim (mm²) | Element raqami | Olchamlari (mm) | AWG | ||||||

| L | W | D | C |

| L | W | D | C | ||||||

| 0,25 | EN0206 | 6 | 1.5 | 1.1 | 0,8 | #26 |

| 10 | EN10-18 | 18 | 5.8 | 4.9 | 4.5 | #8 |

| EN0208 | 8 |

| EN10-20 | 20 | ||||||||||

| 0,34 | EN0306 | 6 | #24 |

| EN10-25 | 25 | ||||||||

| EN0308 | 8 |

| 16 | EN16-12 | 12 | 7.2 | 6.2 | 5.8 | #6 | |||||

| 0,5 | EN0506 | 6 | 1.7 | 1.3 | `1,0 | #22 |

| EN16-16 | 16 | |||||

| EN0508 | 8 |

| EN16-18 | 18 | ||||||||||

| EN0510 | 10 |

| EN16-20 | 20 | ||||||||||

| EN0512 | 12 |

| EN16-22 | 22 | ||||||||||

| 0,75 | EN7506 | 6 | 1.9 | 1.5 | 1.2 | #20 |

| EN16-25 | 25 | |||||

| EN7508 | 8 |

| 25 | EN25-12 | 12 | 9.1 | 7.9 | 7.5 | #4 | |||||

| EN7510 | 10 |

| EN25-16 | 16 | ||||||||||

| EN7512 | 12 |

| EN25-18 | 18 | ||||||||||

| 1.0 | EN1006 | 6 | 2.2 | 1.7 | 1.4 | #18 |

| EN25-22 | 22 | |||||

| EN1008 | 8 |

| EN25-25 | 25 | ||||||||||

| EN1010 | 10 |

| 35 | EN35-16 | 16 | 10.2 | 8.7 | 8.3 | #2 | |||||

| EN1012 | 12 |

| EN35-20 | 20 | ||||||||||

| EN1018 | 18 |

| EN35-25 | 25 | ||||||||||

| 1.5 | EN1508 | 8 | 2.5 | 2.0 | 1.7 | #16 |

| 50 | EN50-12 | 12 | 12.7 | 10.9 | 10.3 | #1 |

| EN1510 | 10 |

| EN50-18 | 18 | ||||||||||

| EN1512 | 12 |

| EN50-22 | 22 | ||||||||||

| EN1518 | 18 |

| EN50-25 | 25 | ||||||||||

| 2.5 | EN2506 | 6 | 3.3 | 2.6 | 2.3 | #14 |

| 70 | EN70-22 | 22 | 15.8 | 14.3 | 13.5 | 2/0 |

| EN2508 | 8 |

| EN70-25 | 25 | ||||||||||

| EN2510 | 10 |

| EN70-32 | 32 | ||||||||||

| EN2512 | 12 |

| 95 | EN95-25 | 25 | 17.3 | 15.6 | 14.8 | 3/0 | |||||

| EN2518 | 18 |

| EN95-30 | 30 | ||||||||||

| 4 | EN4009 | 9 | 3.9 | 3.2 | 2.8 | #12 |

| EN95-34 | 34 | |||||

| EN4012 | 12 |

| 120 | EN120-30 | 30 | 20.2 | 17.7 | 16.7 | 4/0 | |||||

| EN4018 | 18 |

| EN120-34 | 34 | ||||||||||

| 6 | EN6010 | 10 | 4.7 | 3.9 | 3.5 | #10 |

| EN120-38 | 38 | |||||

| EN6012 | 12 |

| 150 | EN150-32 | 32 | 23 | 20.6 | 19.6 | 250/300 | |||||

| EN6018 | 18 |

| EN150-40 | 40 | ||||||||||

| 10 | EN10-12 | 12 | 5.8 | 4.9 | 4.5 | #8 |

| 185 | EN185-32 | 32 | 23.9 | 21.4 | 20.2 | 300/350 |

| EN10-16 | 16 |

| EN185-40 | 40 | ||||||||||

-

Tashqi-arra tishli-kabel bog'lovchi tashqi tishli

-

3,6 mm o'z-o'zidan qulflanadigan neylon simi

-

SHIYUN Ayol o'chirish terminallari

-

Neylon simi bog'lash uchun kesish va mahkamlash vositasi ...

-

Issiqlik bilan barqarorlashtirilgan o'z-o'zidan qulflanadigan neylon simi taqish

-

Identifikatsiya belgisi kabeli